Choosing between digital printing and flexographic printing is a key decision when producing industrial

labels. These are two of the most commonly used printing techniques today, each offering unique

advantages for specific applications that directly impact the quality, cost, and efficiency of the printing

process. In this blog post, we’ll explore both options to identify which is the most suitable based on your

project’s production needs, volume, and material type.

Flexographic vs. Digital Printing

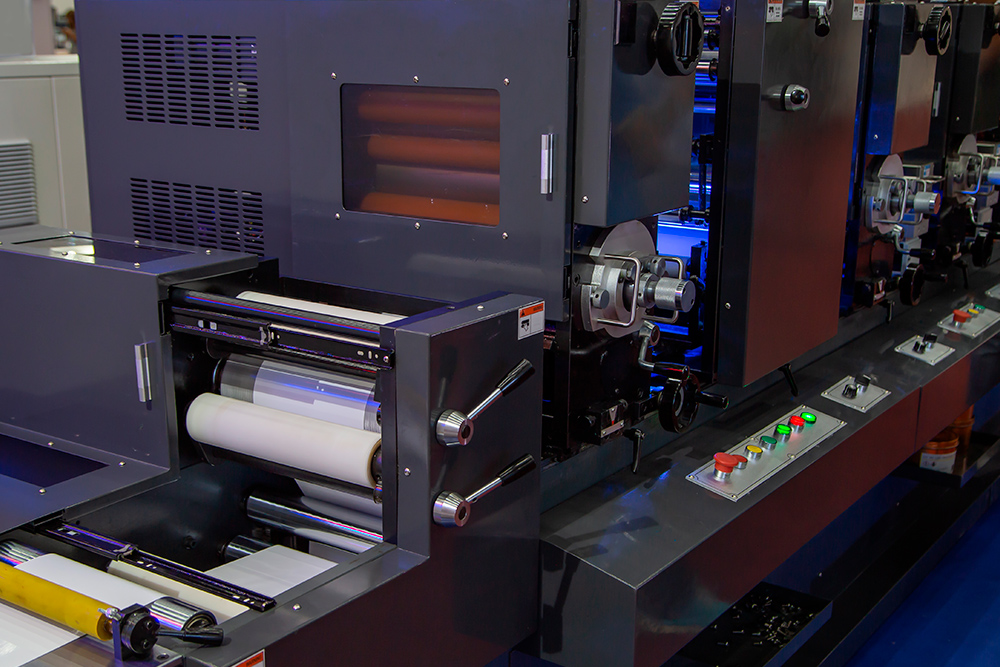

Flexographic printing is a traditional method that uses flexible rubber or photopolymer plates to transfer

fast-drying inks onto materials. It’s ideal for industries where standardization is essential, providing an

efficient and cost-effective solution for high-volume production.

On the other hand, digital printing is a modern technology that prints directly from a digital file onto

various substrates. Unlike flexography, it does not require the creation of physical plates, reducing setup

times and increasing accuracy when reproducing fine details.

Benefits of Flexographic and Digital Printing

Both flexographic and digital printing have evolved to meet the demands of the market, each offering

ideal advantages for different production scenarios. These technologies provide versatile solutions for

companies looking to enhance the presentation of their labels. Below are some key benefits of each

method:

Flexographic Printing

Flexography is an excellent choice for long-run production due to factors such as:

- Cost-effectiveness for large volumes: The larger the quantity, the lower the unit cost—making it

- ideal for industries such as food, pharmaceuticals, and automotive.

- Inclusion of special finishes: Finishes such as varnishes, embossing, or lamination can be

- incorporated during the same printing process.

- Compatibility with a wide range of materials: From plastic films, paper, and corrugated

- cardboard to metallic substrates, flexography can print on a broad variety of surfaces.

- High durability: Perfect for industrial products that must withstand humidity, heat, or friction.

Despite these benefits, it’s important to consider that flexographic printing requires more preparation

time and specialized technical personnel, which may result in higher initial costs for small print runs.

Digital Printing

In such cases, digital printing may be a more cost-effective option, offering advantages like:

- Fast turnaround: With no need to create plates or make major adjustments, setup times are

significantly reduced. - Flexibility for short runs: Ideal for sectors with frequent changes and small-batch label printing,

as it’s more economical. - Sustainability: Produces less waste, uses less ink, and requires no physical plates—making it an

eco-friendlier choice. - High quality and precision: Allow for complex images to be printed with great detail and

accurate color reproduction, even for vibrant hues.

That said, it’s also important to note that digital printing typically has a higher unit cost for large runs

and may sometimes require additional processes for special finishes or increased durability.

How to Choose Between Flexographic and Digital Printing?

As discussed above, both printing techniques offer significant differences that should be carefully

considered when selecting the right technology for your company’s industrial labels:

- Ideal print volume: Digital printing is optimal for short runs, while flexography is best suited for

large quantities. - Available production time: For projects with tight deadlines, digital printing is ideal, as

flexography involves longer setup times. - Design versatility: Digital printing makes design customization easier, whereas flexography has

more limitations in this regard. - Material compatibility: Flexography adapts to a wider range of substrates, while digital printing may have more restrictions.

You should also consider factors such as sustainability, unit cost, and the need for special finishes, as

these will influence which option is most cost-effective for your business.

Label Printing at Taylor: Quality, Innovation, and Flexibility

At Taylor Mexico, we specialize in the production of industrial labels with the highest quality standards.

We offer specialized technologies, including flexographic and digital printing, allowing us to fully adapt

to the specific needs of each client and provide versatile, efficient, and high-quality solutions.

Our printing systems are certified under standards such as ISO 9001:2015, IATF 16949, and UL, ensuring

that each label meets the technical and regulatory requirements of industries such as automotive,

HVAC, and electrical, among others. Whether you need flexibility, volume, or both—Taylor has the

technology and expertise to take your project to the next level. Contact us and discover how we can

help you.